Rack Protection

One of the foremost challenges in the storage industry is minimizing the potential harm to pallet racking systems. LinkMisr is actively engaged in advocating for the secure utilization of storage equipment.

Several prerequisites are in place to reduce the likelihood of damage, including:

It is imperative for the user to designate a competent individual as the Rack Safety Responsible Person. This role involves ensuring that the racking systems adhere to relevant regulations and guidelines in terms of usage, inspection, and maintenance.

Users must ensure that operators receive proper training on the appropriate use and limitations of storage equipment. The user bears the responsibility of maintaining the racking in a reasonably fit condition. Comprehensive training for operators is crucial in reducing the potential for accidents.

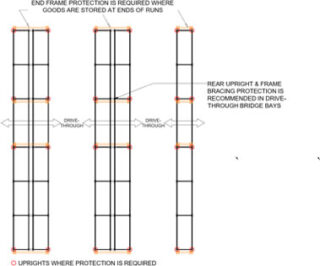

In racking systems operated by trucks, it is recommended to install end frame protectors for all end frames located between gangways and aisles, as well as between bridge bays and aisles. Additional protection measures for racking should be identified based on a risk assessment. Users should be mindful of the effects of retrofitting protection devices, as they might decrease operating clearances and, in some cases, lead to increased damage.

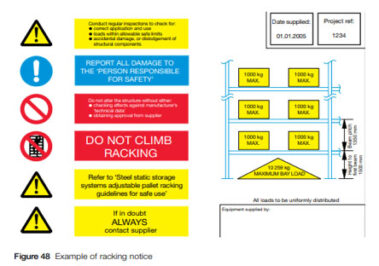

Regular inspections of pallet racking are obligatory. These inspections should be approached hierarchically through three levels:

• Warehouse operatives conducting damage inspections.

• Weekly visual checks from ground level.

• Annual or bi-annual inspections performed by technically competent individuals.

Any damaged component, noted during inspection as requiring repair or replacement, should be taken out of use in accordance with SEMA guidelines and repaired or replaced by suitably trained personnel as required.

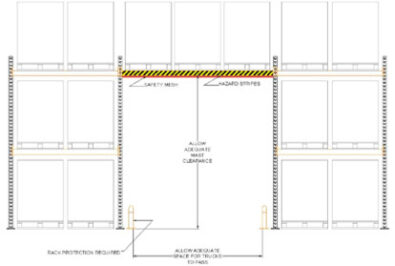

Typical racking protection requirements are shown in Figures 1 and 2.

Figure 1. Plan view of racking showing typical protection requirements

Figure 2. Elevation of racking showing typical protection requirements at a bridge bay

Another important document regarding the safe use of pallet racking is the HSE document HSG 76, Warehousing and storage, A guide to health and safety.’ This can be downloaded free from the HSE website.

The HSE document has various requirements which will minimize damage including the following paragraphs on rack protection: –

For increased safety, many racking suppliers consider it prudent to secure all uprights to the floor. Floor fixing should be such that the anticipated horizontal shear and vertical tensile forces can be safely resisted

Where racking is likely to be struck by lift trucks and other vehicles, it should be protected. Generally, such damage is at the lower levels of the racking – use renewable column guards to minimize the risk of damage from accidental impact. Corner uprights in a run of racking are especially at risk and should be suitably provided with a protective device in a conspicuous colour.

Retrofitting upright protection devices to an existing aisle where they have never been provided can have the effect of reducing the available clearances for fork-lift truck manoeuvres, which can in some circumstances increase the amount of damage caused. Such situations need consideration on a case-by-case basis.

Whether you’re unsure about the structural integrity of your existing pallet racking system or simply want to keep up to date with best practices for a safe working environment, Contact Us TODAY

ADDED VALUE

SERVICES